11.2 Tool Compensation Commands

G43/G49: Tool Length Compensation/Cancel Tool Length Compensation

Format:

G43 H_

G49

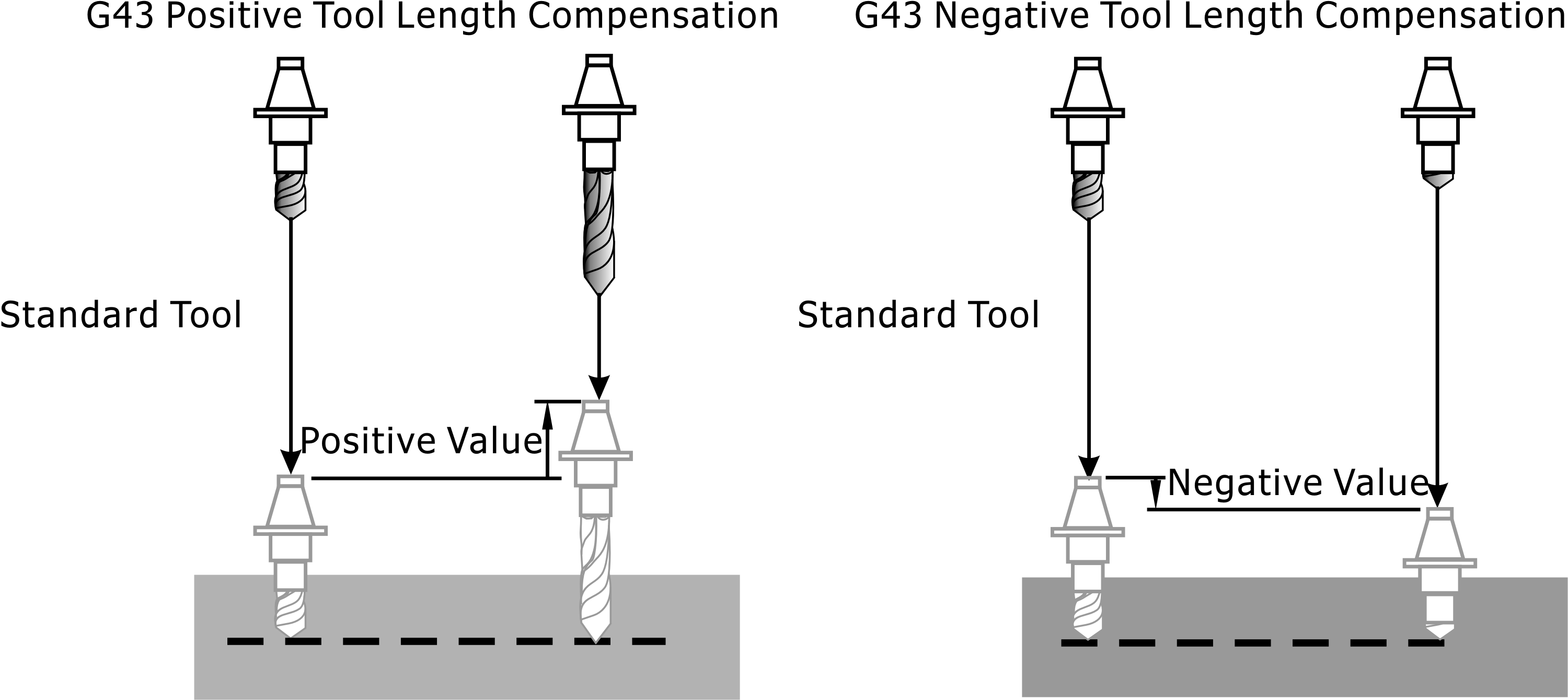

The tool used in the CNC milling machine is different in the length of each tool. Therefore, the tool length must be corrected for each tool so that the machining depth of each tool is correct. G43 can start the tool length compensation function. In the tool table, H_ value refers to the positive and negative values in the tool length column, and determines the positive and negative direction and length of the compensation. The value in this column refers to the difference when compared with the standard tool length. If the new tool is longer than the standard tool, this value is positive; if the new tool is shorter than the standard tool, this value is negative.

G43 is a continuous valid command. If you want to cancel the tool length compensation function, execute G49 or H00. (G49: Tool length compensation canceled. H00 indicates that the compensate value is zero)

G43: Tool Length Compensation (Positive/Negative)

G40/G41/G42: Tool Radius Compensation

Format:

G41 D_

G42 D_

G40

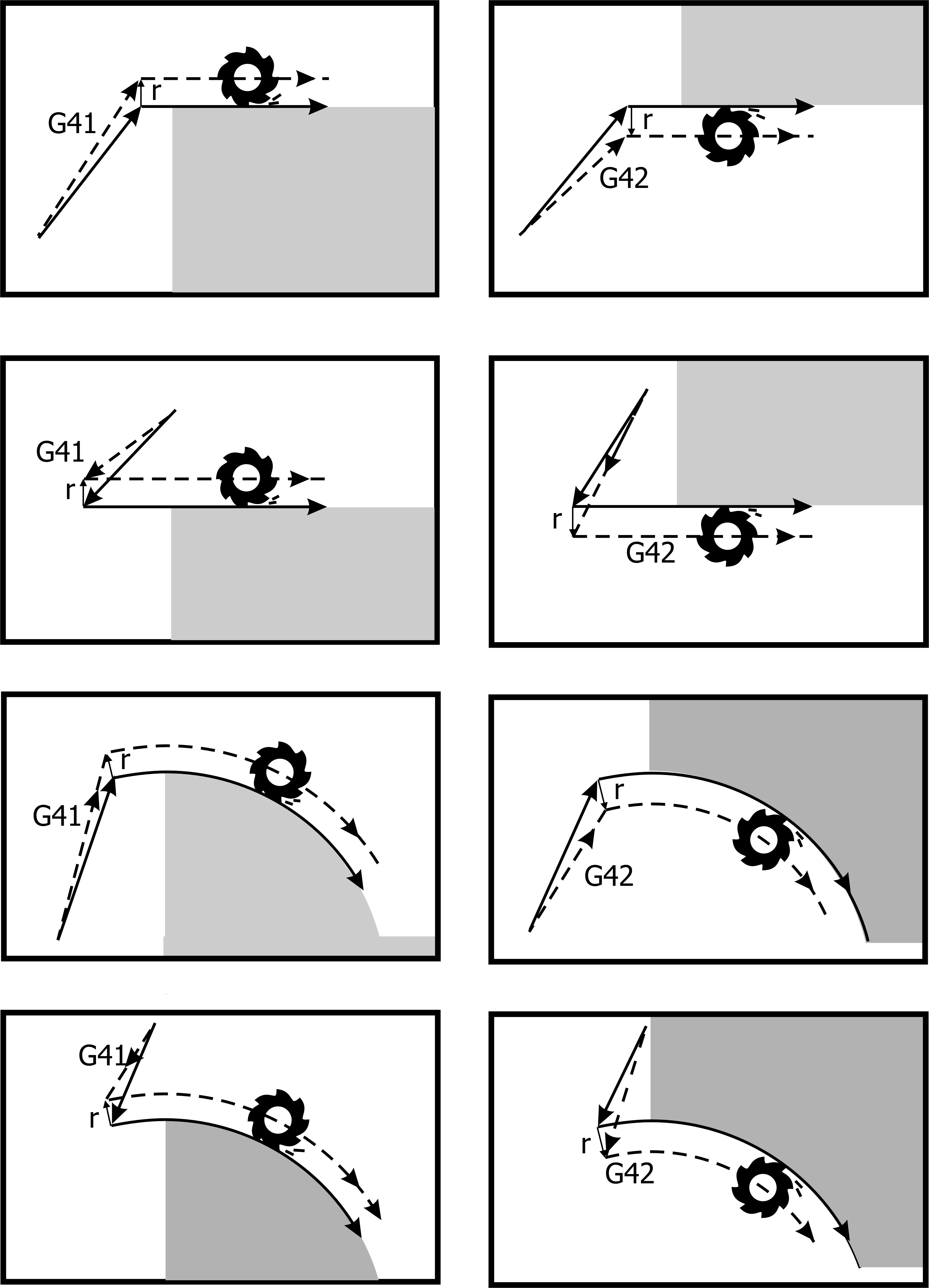

G41/G42 starts tool radius compensation and offsets the tool to the left/right of the starting point of the workpiece contour to be cut. Tool radius compensation left/right deviation judgement is based on the following definition: In the cutting path of the program, from the direction of cutting advance, the right cutter of the milling cutter is executed with G42 command; if the cutter is left offset, G41 command is used carried out.

When editing a program, only the tool number, such as D01, D02..., must be entered. The set D_ represents the tool number in the "Setting→Tool Table", and the offset of tool radius compensation is the radius compensation value set by this tool number. This radius compensation value is the user's parameter before processing "Setting→Tool Table" setting. For example: D02 indicates that the tool number is No. 2, and the radius compensation value No. 2 is 4.0, indicating that the cutter radius is 4.0 mm.

When executing the G41 or G42 command, the controller will use the radius value of the tool number specified by D_ as the compensation value. The D_ value is still memorized by the controller after being turned off until it is replaced by a new D_ value; if it is set to D00, it will be regarded as not making any tool radius compensation.

When performing tool radius compensation, the compensation state must be cancelled with G40 after the machining is completed, and the center point of the milling cutter should be returned to the actual coordinate point. In other words, when executing G40 command, the system will move in the opposite direction to the original left or right compensation value. When using G40, please make sure that the milling cutter is away from the workpiece to avoid damage.

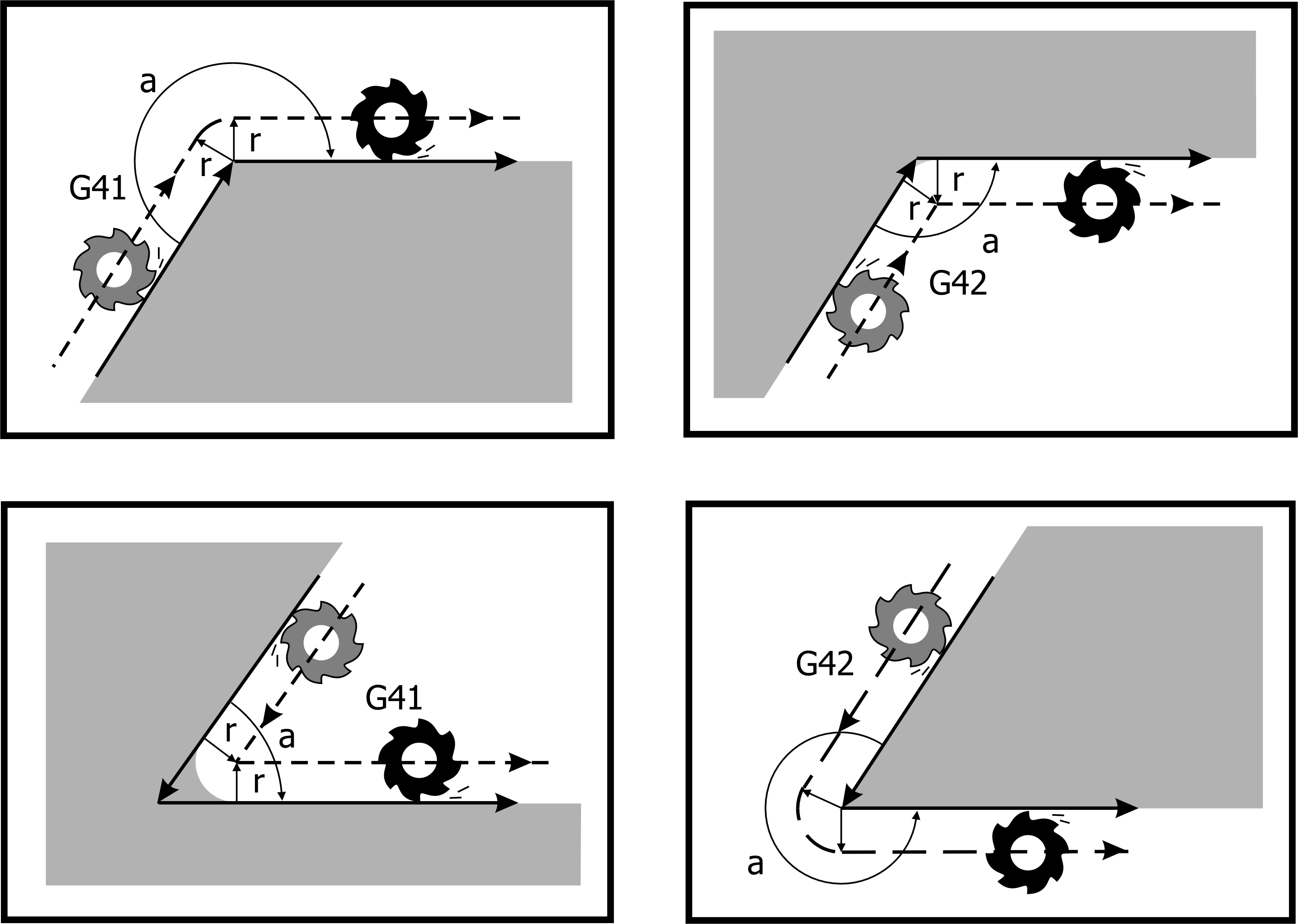

In compensation mode, the system will perform tool radius compensation according to the following principles:

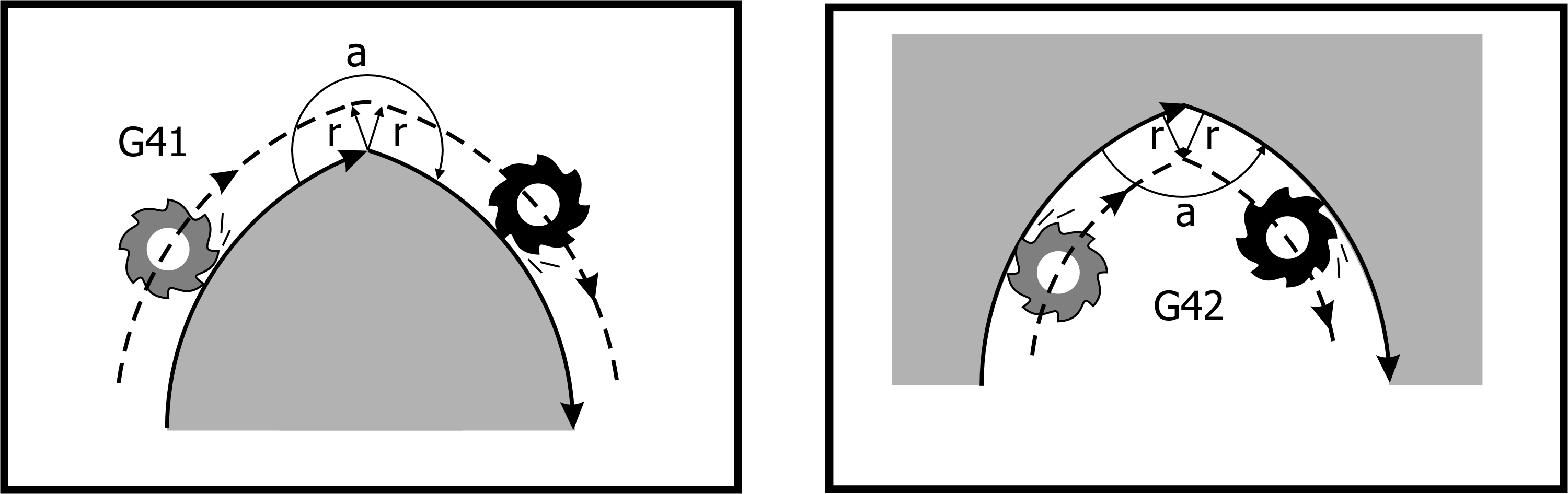

1. Corner path when the workpiece convex cutting:

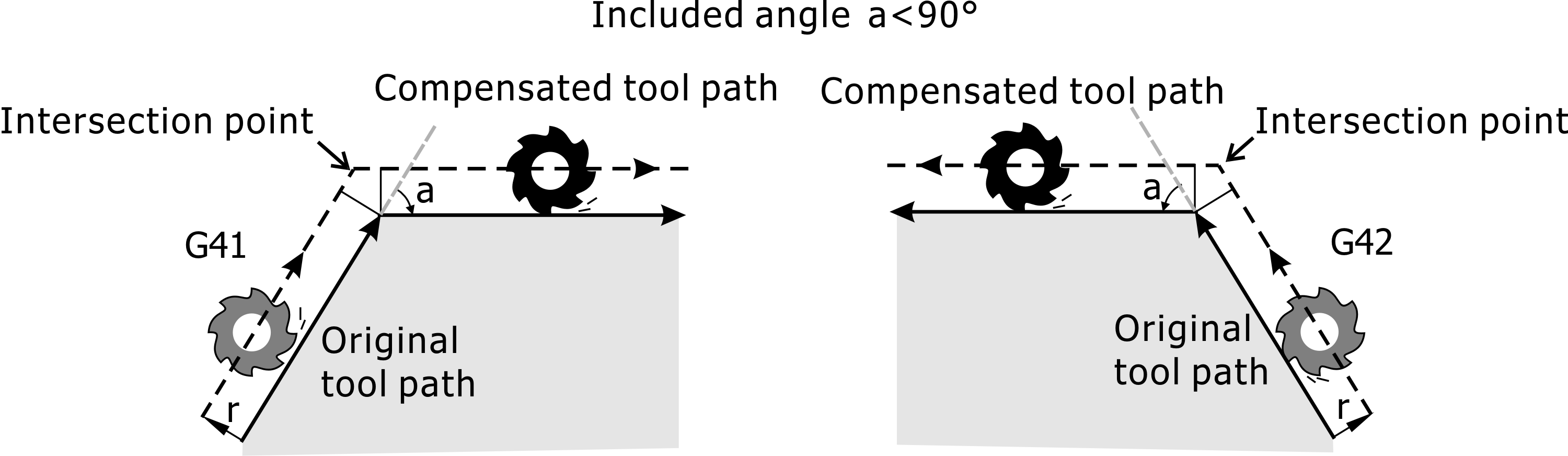

(1) |

When the included angle is less than 90 degrees: When the angle between the two path vectors is less than 90 degrees, the workpiece convex surface corner paths are processed by intersection, the CNC controller automatically calculates the intersection of these two paths. This intersection point becomes the starting point of the previous block and the starting point of the back block. |

Intersetcion Point of Tool Paths with an Included Angle Less Than 90 Degrees

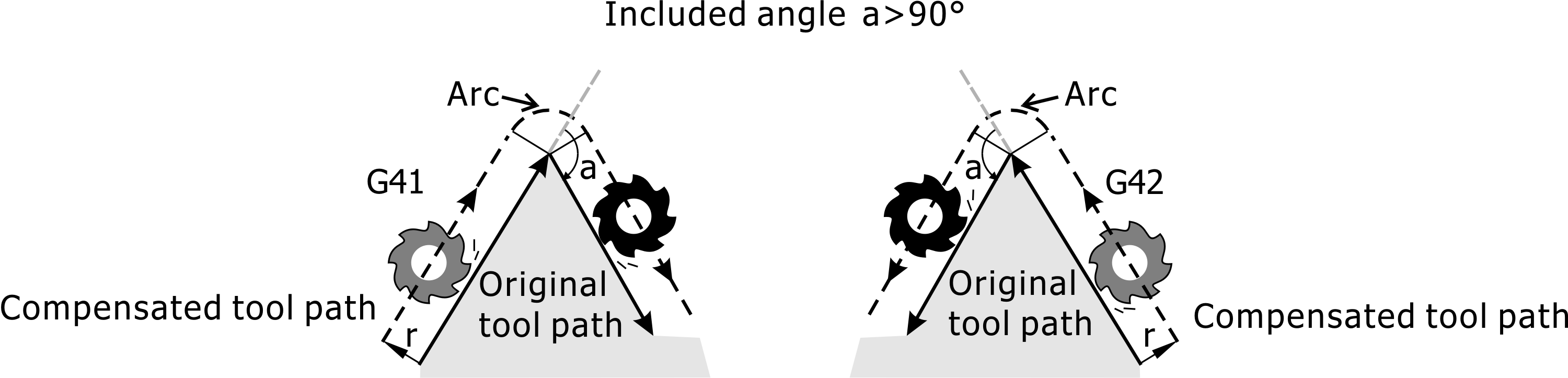

(2) |

When the included angle is greater than 90 degrees: When the angle between the two path vectors is greater than 90 degrees, the corner path of the workpiece convex surface is treated with an arc. |

Arc Corner of Tool Paths with an Included Angle Greater Than 90 Degrees

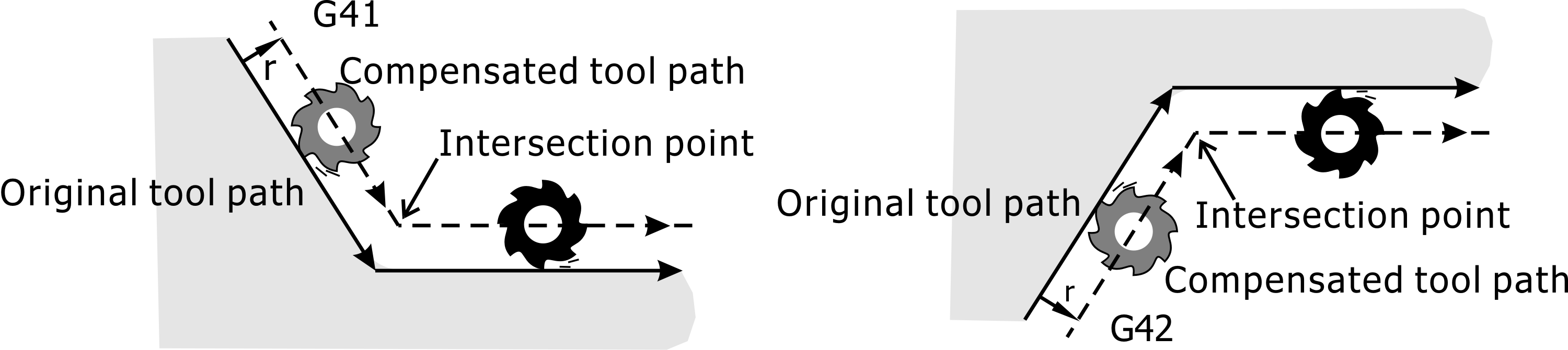

2. |

Path at concave: system auto calculates two path intersection, and this intersection became pre block end position and start position of back block. |

Intersetcion Point of Tool Paths When Cutting the Concave Side of Workpiece

Note 1: |

The compensation train in block only allow to use linear interpolate command (G00/G01), otherwise if arc interpolate command (G02/G03) used will alarm and stop. |

Note 2: |

To change tool radius, or to toggle G41, G42 mode in tool compensation were not allow. |

• G41/G42: Start-up of Tool Radius Compensation

Tool compensation train in command must pre block of cutting path, after train in tool compensated, the cutting path will offset left or right a tool radius. The solid line is path without compensation.

G41/G42: Start-up of Tool Radius Compensation

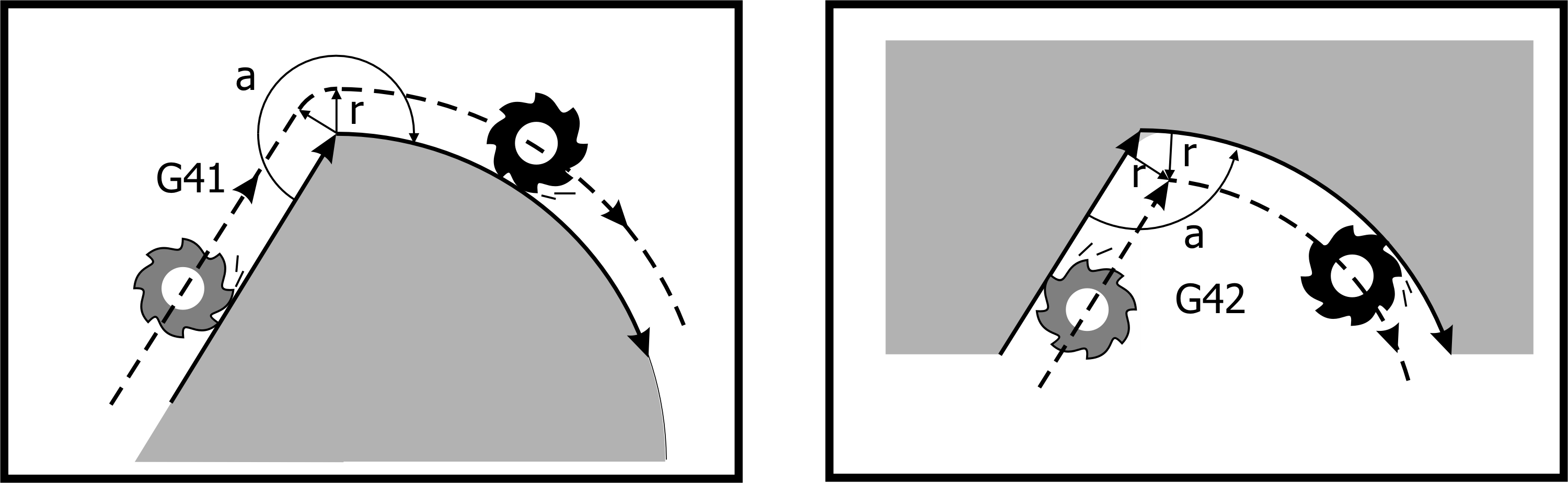

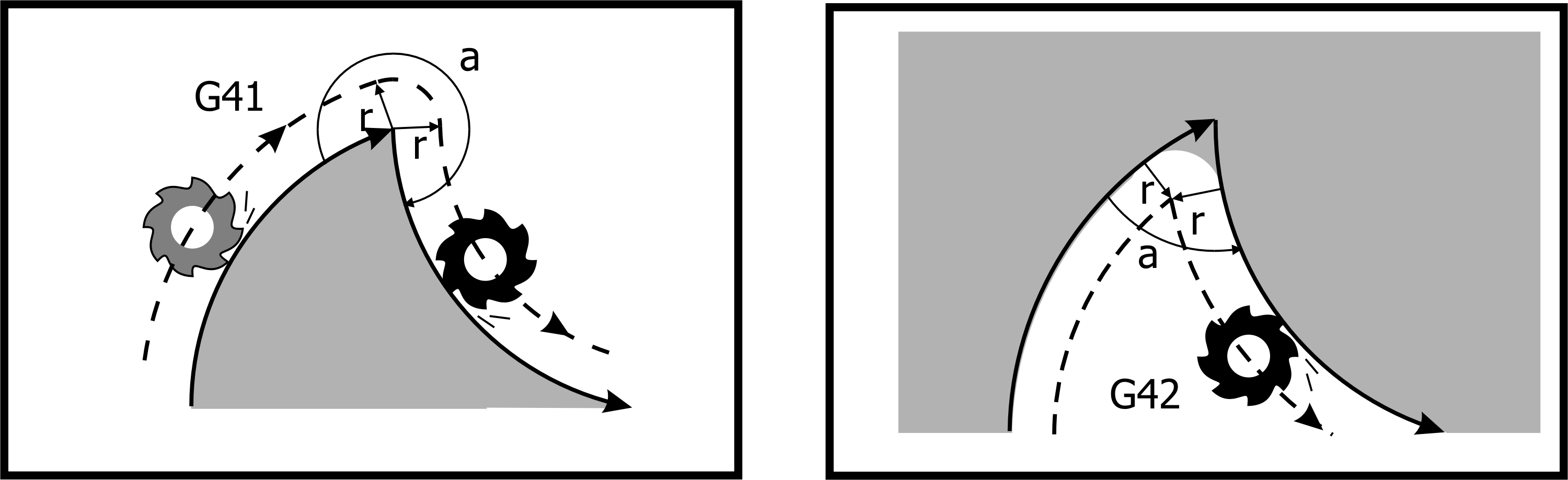

• G41/G42: During Tool Radius Compensation

1. Straight-line to Straight-line

During Tool Radius Compensation: Straight-line to Straight-line

2. Straight-line to Arc

(1) Straight-line to clockwise arc

Tool radius compensation: from straight line to CW

(2) Straight-line to counterclockwise arc

During Tool Radius Compensation: Straight-line to Counterclockwise Arc

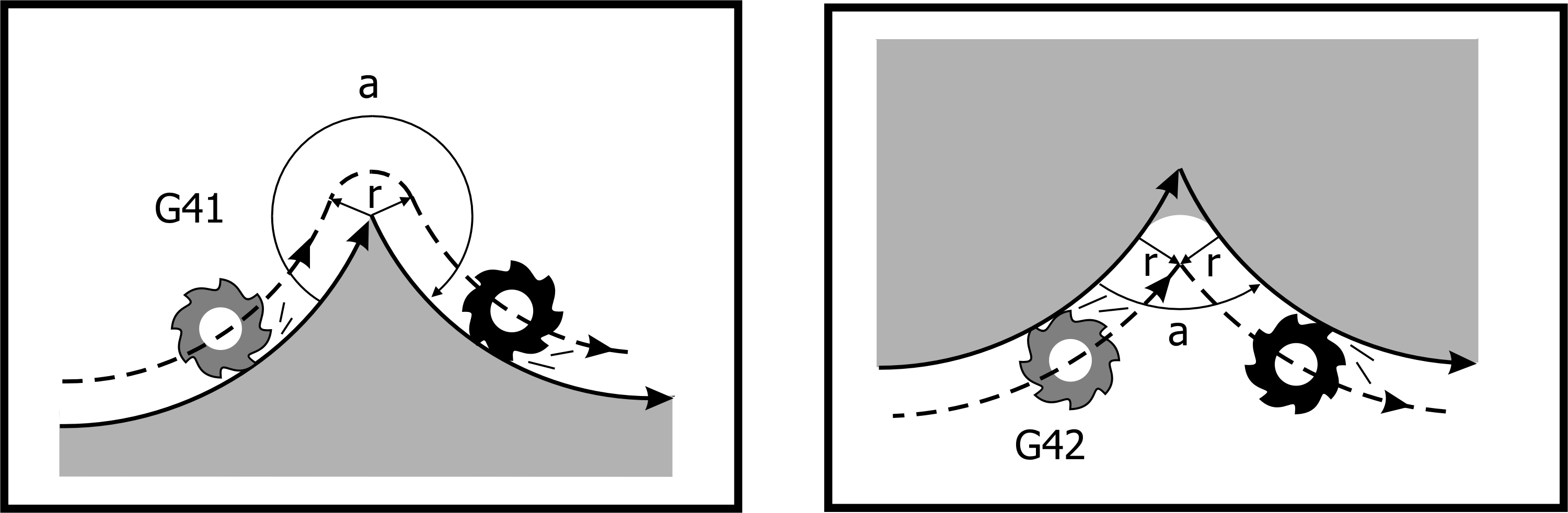

3. Arc to Arc

(1) Clockwise arc to clockwise arc

During Tool Radius Compensation: Clockwise Arc to Clockwise Arc

(2) Clockwise arc to counterclockwise arc

During Tool Radius Compensation: Clockwise Arc to Counterclockwise Arc

(3) Counterclockwise arc to counterclockwise arc

During Tool Radius Compensation: Counterclockwise Arc to Counterclockwise Arc

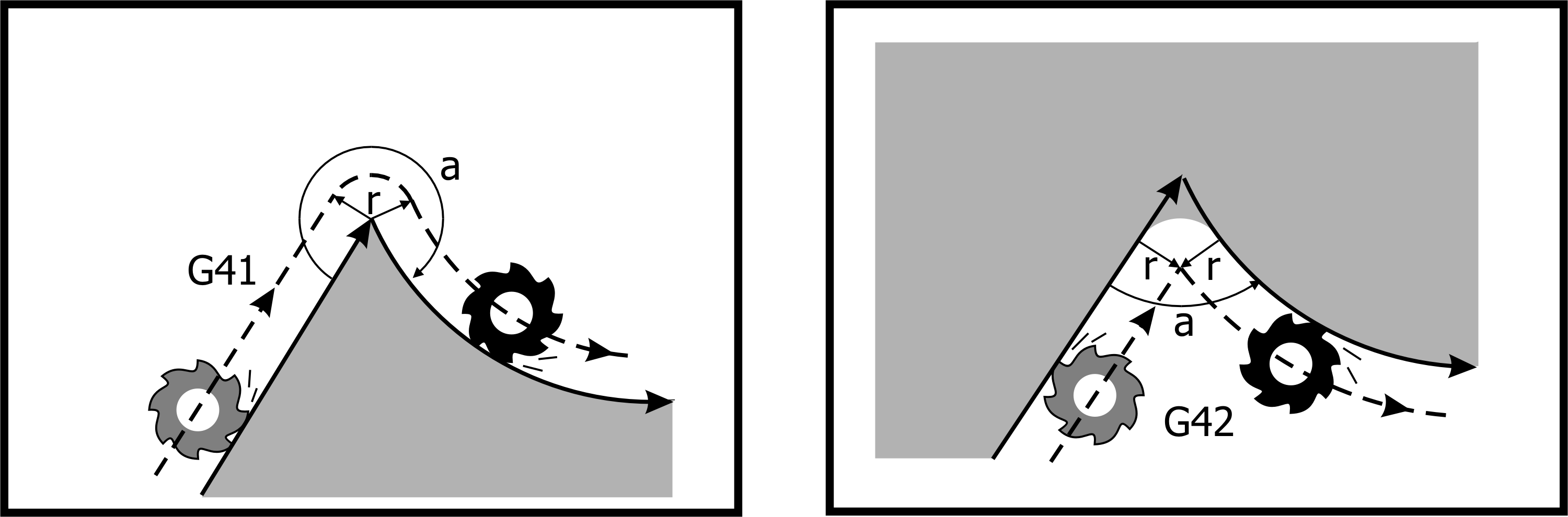

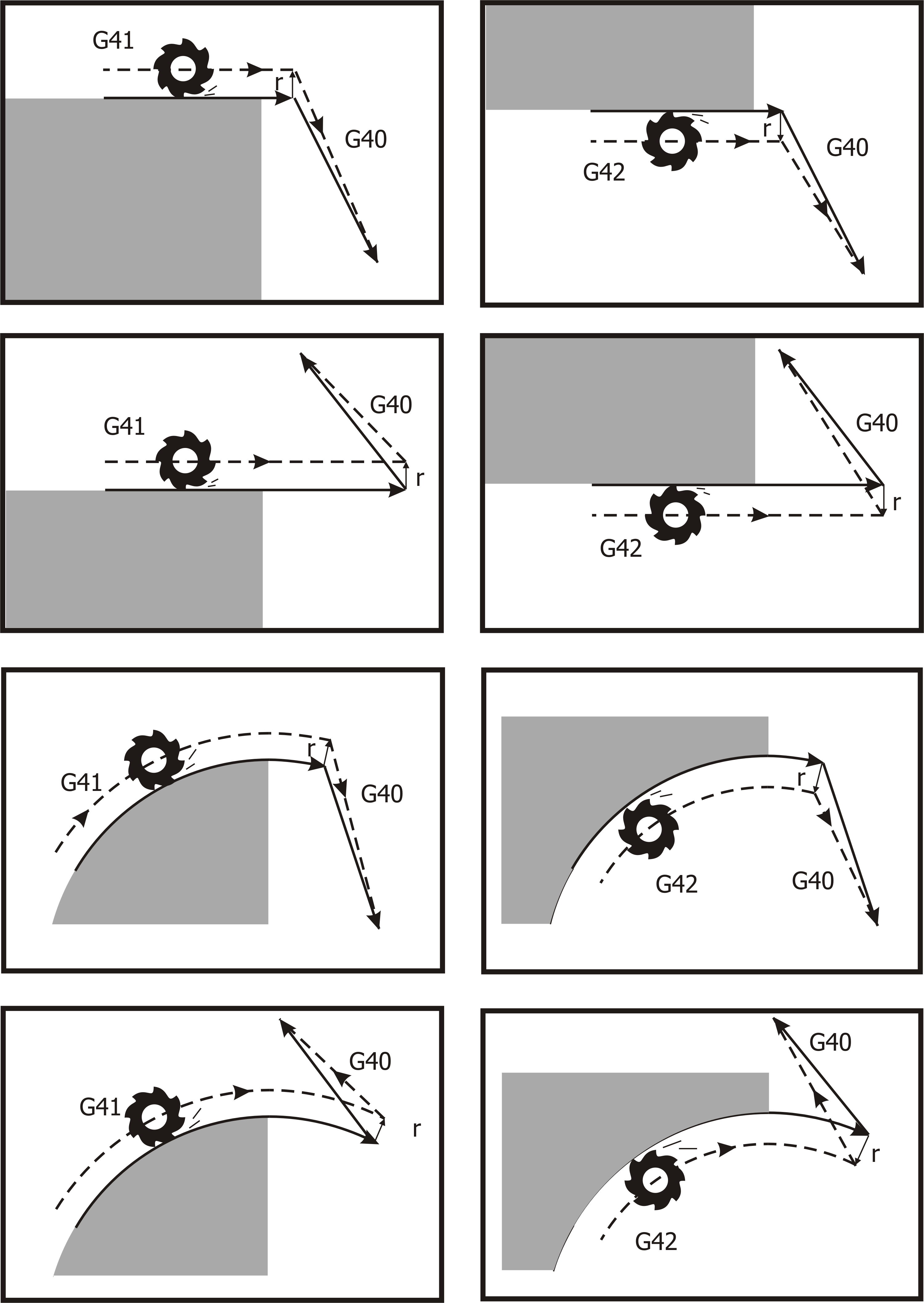

• G40: Cancelling Tool Radius Compensation

Tool radius compensation cancels compensation at the end of the path to the original tool tip point.

G40: Cancelling Tool Radius Compensation