11.4 Spindle Control Commands

M03/M04/M05: Spindle On Clockwise / Spindle On Counterclockwise / Spindle Stop

Format:

M03 S_ : Spindle rotates clockwise

M04 S_ : Spindle rotates counter clockwise

M05 : Spindle stop

When M03/M04/M05 and the axial feed command are on the same line, the machine factory usually designs the M03/M04 and axial feed simultaneously with the PLC planning and M05 is executed after the axial feed is completed. M03/M04/M05 should be separated by one line as much as possible to avoid that the cutting speed has not been reached yet, or that the spindle has stopped rotating while cutting.

S Code: Spindle Speed Setting

Format:

Sxxxxxx : Spindle speed per minute in rpm

The spindle rpm is usually expressed as a 4-digit number up to 6 digits. The S code is only used to set the spindle speed and does not cause the spindle to rotate. When the M03 (spindle forward) or M04 (spindle reverse) command is required, the spindle will start to rotate.

G94/G95: Feed rate control per minute/per revolution

Format:

G94 F_

G95 F_

M83 G95 command is designed to specify the pitch of Rigid Tapping.

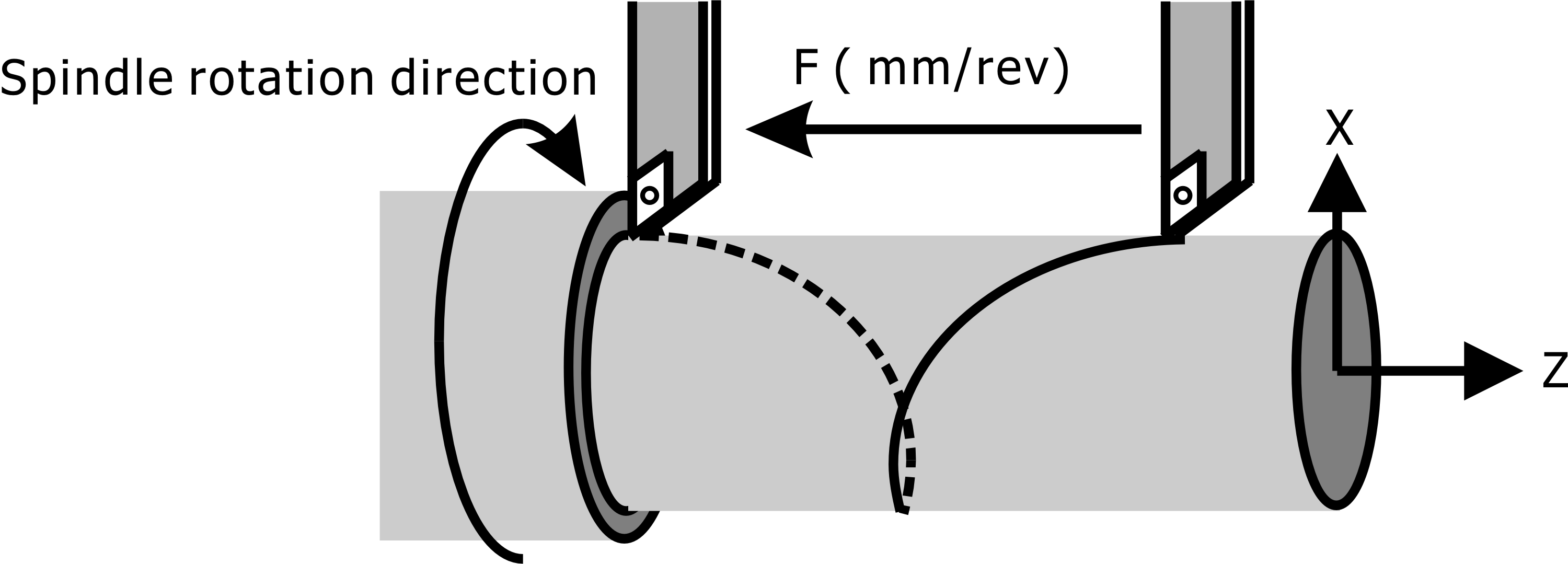

The G95 command setting F_ is the feed speed per revolution. The tool cuts the surface of the workpiece in accordance with the speed at which the spindle moves F_ each time. The G94 command cancels the feed rate control per revolution (ie, G95 mode) and restores the feed rate per minute with F_.

Feed Rate in Millimeters (Inches) per Revolution

Note: |

In the G94 and G95 instructions, the F_ values are defined differently as follows: |

1. |

If the F_ value in G94 is not given to the decimal point, it will be treated as having a decimal point after the mantissa. If the value given is a decimal, the decimal is still valid; therefore, F300 will be treated as F300.0, while F300.05, F300.6 and other decimals are still valid. |

2. |

If the F_ value in G95 is not given a decimal point, it will be converted to an integer multiple of the minimum unit of the system. If the value given is a decimal, the decimal is still valid; therefore when the minimum unit of the system is 0.001, F300 will be treated as if it is F0.300, and the fractions such as F300.05 and F300.6 are still valid. |

3. |

From the above definition, the range of F_ values can be sorted out: |

G21 (Metric unit input) |

G20 (Inch unit input) |

|

G94 mode feed per minute |

F0.001~F60000 (0.001~60000 mm/min) |

F0.0001~F2362 (0.0001~2362 inch/min) |

Feed per revolution in G95 mode |

F0.001~F999.999 (0.001~999.999 mm/rev) |

F0.0001~F39.3700 (0.0001~39.3700 mm/rev) |