1 Introduction

INCON-M83 CNC controller (Following manual abbreviates it to M83) is an economical CNC system which is easy to integrate and operate, high reliability and low maintenance cost. It could apply on milling machines that do not require auto tool changing feature. And it is very beneficial for retrofitting CNC feature to a conventional milling machine.

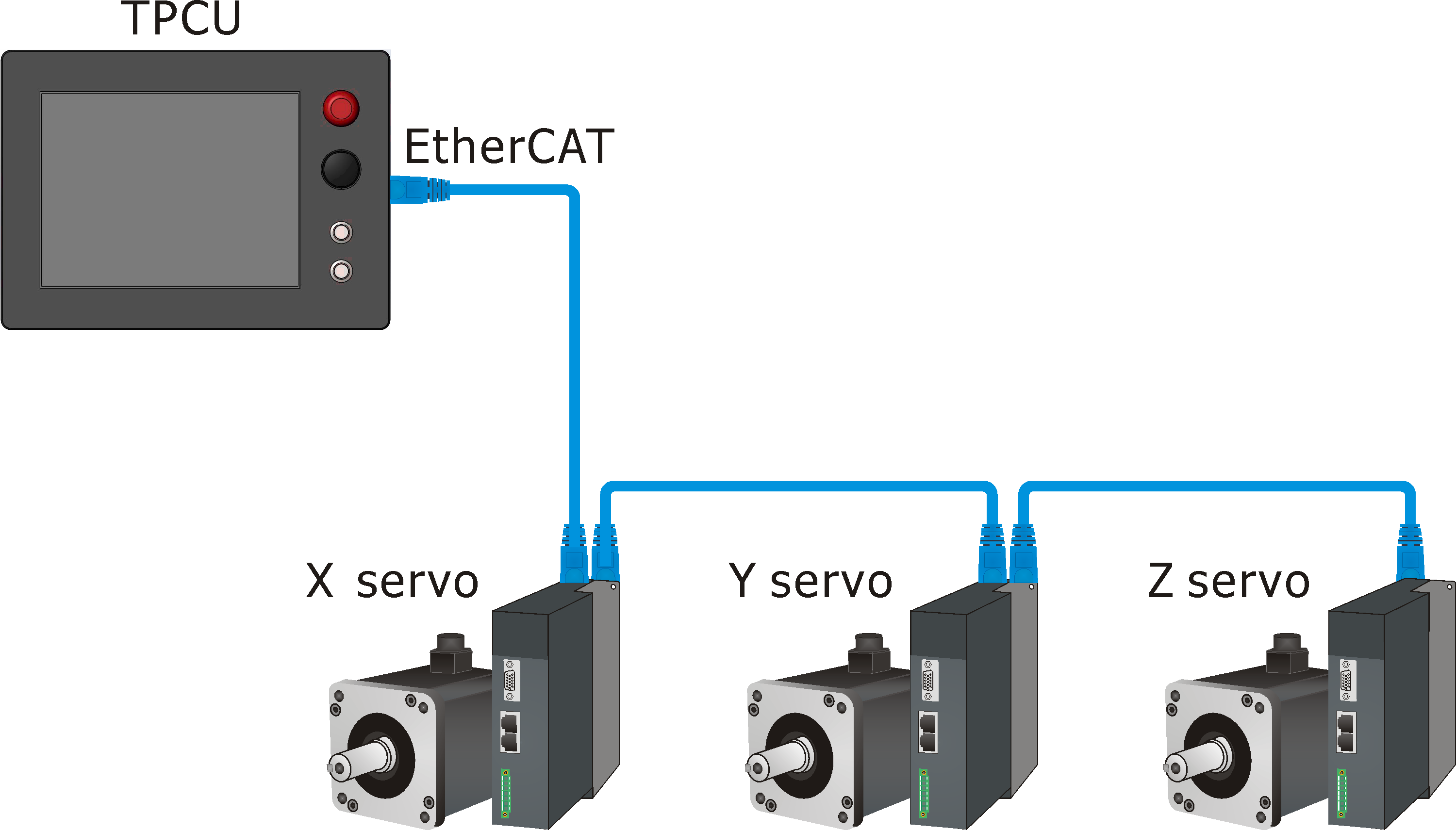

The M83 system includes the main control unit TPCU, servo drivers/motors, and a input/output unit ESPU, which is an optional component. The following figure is a typical XYZ configuration of three-axis EtherCAT servo and M83 control system.

M83 has the following features:

Concise wiring and connection

EtherCAT communication technology is used to connect between M83 and servo system. A compact system composition makes it easy to arrange the electrical distribution.

User friendly interface

M83 provides touch screen, push buttons, rotary knob and highly accessible user interface, which makes the operation intuitive and simple.

Built-in practical machining objects

INSMILL milling objects only need a few geometry and manufacture factors, and it could generate milling processes of various shapes, such as face milling, pocket milling, drilling, etc. There is no need for user to write a CNC file with these objects.

No homing need

Rely on a servo motor with an absolute encoder, there is no need to return to zero after restart. And the limit switch is not needed as well.

Metric and Imperial supported

Whether the lead screw is in mm or inch, M83 could be used in metric or imperial units.

High performance triaxial CNC function

If ESPU is purchased, M83 would has the functions of three-axis synchronized motion, high-speed high-precision and rigid tapping.