9.4 Polygonal Pocket Milling

Polygonal pocket milling means a repeatedly down cutting to designated depth in a polygonal area.

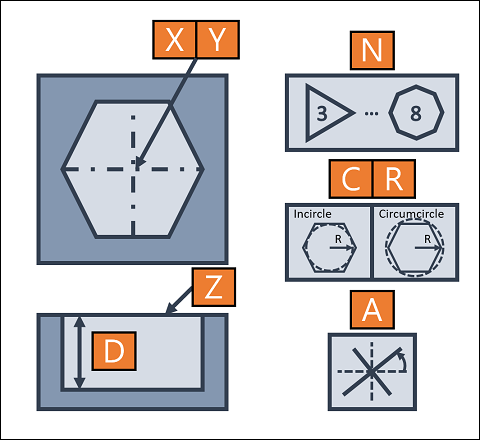

Geometry

X CenterX |

The distance from the origin of workpiece to the center of the polygon in X direction. |

|

Y CenterY |

The distance from the origin of workpiece to the center of the polygon in Y direction. |

|

Z StartZ |

The distance from the origin of workpiece to the upper surface of removed area in Z direction. |

|

N N-sided |

Number of sides. Range from 3 to 8. |

|

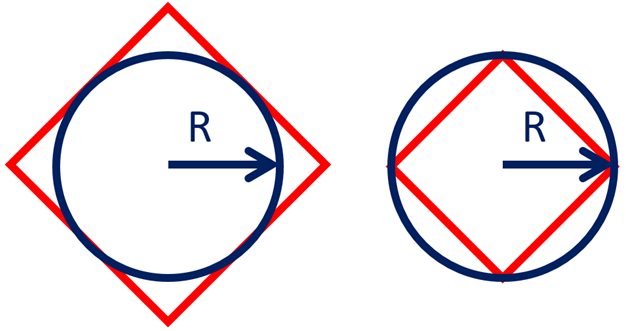

C Circle |

In |

The reference circle is the incircle of this polygon, which means the reference circle is tangent to all sides of this polygon. |

Circum |

The reference circle is the circumcircle of this polygon, which means the reference circle passes through all vertices of this polygon. |

|

R Radius |

Radius of reference circle. |

|

D Depth |

Depth of removal. |

|

A Rotate |

A counterclockwise rotation around the center with designated angle. |

|

Note 1: |

One vertex is on the positive direction of X axis while the rotating angle is 0. |

Note 2: |

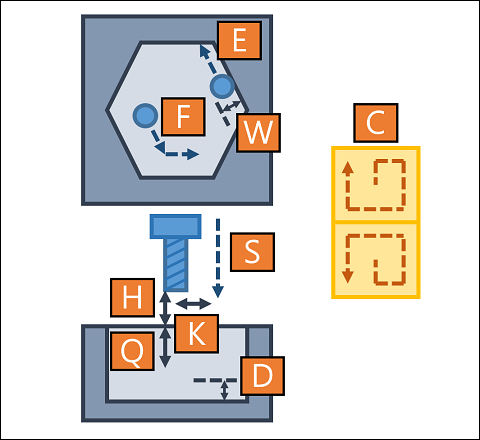

The left graph below shows the Incircle of a polygon, and the right one shows Circumcircle. Here comes the equations when an N-sided polygon defined by In/Circumcircle with radius R.

|

Manufacture

ToolNumber |

Order of desired tool in tool table. |

|

SpindleRPM |

Rotating speed of spindle. |

|

SpindleDir |

CW |

Spindle rotates in CW. |

CCW |

Spindle rotates in CCW. |

|

H ZUpper |

Z axis would halt at this position which is related to StartZ before and after cutting. |

|

C CutDir |

CW |

Direction of cutting route is CW. |

CCW |

Direction of cutting route is CCW. |

|

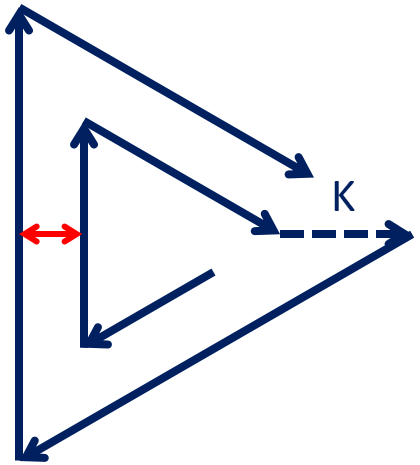

K StepWidth |

Width per cut. Must less than the diameter of selected tool. Set in percentage of tool diameter. |

|

Q StepDepth |

Depth per cut. Must less than or equal to Depth of geometry. |

|

W FineWidth |

Width of fine cut. Set to 0 if none. Must less than or equal to StepWidth and tool radius. |

|

D FineDepth |

Depth of fine cut. Set to 0 if none. Must less than or equal to StepDepth. |

|

F Feedrate |

Feedrate of XY moving. (mm/min) |

|

S ZDirFeed |

Feedrate of Z moving. (mm/min) |

|

E FineFeed |

Feedrate of fine cut. (mm/min) |

|

Note: |

In this process, "K StepWidth" is defined as the step in distance on the vertex-to-vertex direction in order to avoid cutting residues. In below diagram, the dashed arrow is K. And the double arrow shows the edge-to-edge step in distance, which is "K × cos (π×(N-2)/2N)", of an N-sided polygon.

|