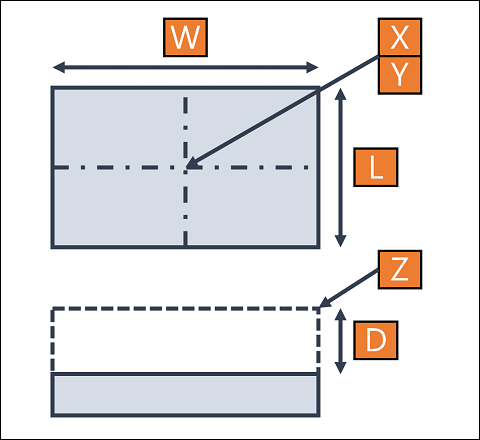

9.1 Face Milling

Face milling means a down cutting to designated depth in a rectangular area which is coaxial to XY axes.

Geometry

X CenterX |

The distance from the origin of workpiece to the center of the rectangle in X direction. |

Y CenterY |

The distance from the origin of workpiece to the center of the rectangle in Y direction. |

Z StartZ |

The distance from the origin of workpiece to the upper surface of removed area in Z direction. |

W Width |

Width of the rectangle. (X direction) |

L Length |

Length of the rectangle. (Y direction) |

D Depth |

Depth of removal. |

Note: |

It would start cutting from the entry point at the upper-left of the rectangle defined by Width/Length, and end up when whole area was swept over. If overtravel distance is required, please modify Width/Length directly to get it. |

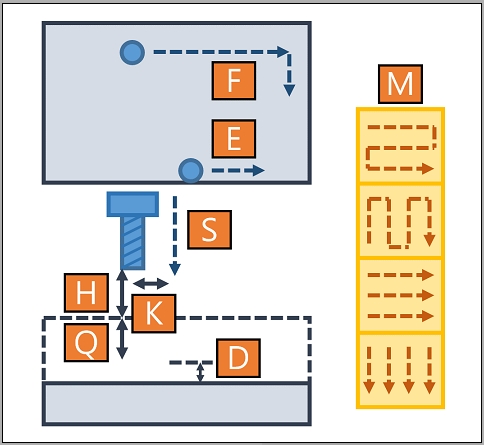

Manufacture

ToolNumber |

Order of desired tool in tool table. |

|

SpindleRPM |

Rotating speed of spindle. |

|

SpindleDir |

CW |

Spindle rotates in CW. |

CCW |

Spindle rotates in CCW. |

|

H ZUpper |

Z axis would halt at this position which is related to StartZ before and after cutting. |

|

M FaceMode |

BiDirX |

Cut the width along X direction, then shift one step in Y. Cut the width back along X direction. |

BiDirY |

Cut the length along Y direction, then shift one step in X. Cut the length back along Y direction. |

|

SglDirX |

Cut the width along X direction, uplift the tool, then shift one step in Y and go back in X simultaneously. |

|

SglDirY |

Cut the length along Y direction, uplift the tool, then shift one step in X and go back in Y simultaneously. |

|

K StepWidth |

Width per cut. Must less than the diameter of selected tool. Set in percentage of tool diameter. |

|

Q StepDepth |

Depth per cut. Must less than or equal to Depth of geometry. |

|

D FineDepth |

Depth of fine cut. Set to 0 if none. Must less than or equal to StepDepth. |

|

F Feedrate |

Feedrate of XY moving. (mm/min) |

|

S ZDirFeed |

Feedrate of Z moving. (mm/min) |

|

E FineFeed |

Feedrate of fine cut. (mm/min) |

|