9.6 Rectangular Island Milling

Rectangular island milling means a repeatedly down cutting to designated depth with a remained rectangular island at the center.

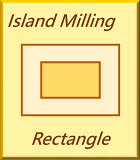

Geometry

X CenterX |

The distance from the origin of workpiece to the center of the rectangle in X direction. |

Y CenterY |

The distance from the origin of workpiece to the center of the rectangle in Y direction. |

Z StartZ |

The distance from the origin of workpiece to the upper surface of removed area in Z direction. |

W InWidth |

Width of the inner rectangle. |

L InLength |

Length of the inner rectangle. |

D Depth |

Depth of removal. |

I OutWidth |

Width of the outer rectangle. |

J OutLength |

Length of the outer rectangle. |

R Fillet |

Fillet radius of the inner rectangle. Set to 0 if none. Fillet and Chamfer are mutually exclusive. |

C Chamfer |

Chamfer length of the inner rectangle. Set to 0 if none. Fillet and Chamfer are mutually exclusive. |

A Rotate |

A counterclockwise rotation around the center with designated angle. |

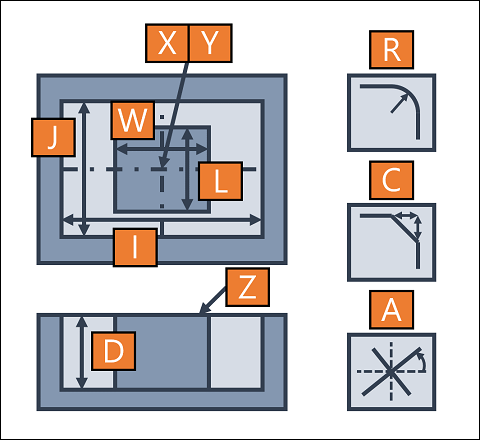

Manufacture

ToolNumber |

Order of desired tool in tool table. |

|

SpindleRPM |

Rotating speed of spindle. |

|

SpindleDir |

CW |

Spindle rotates in CW. |

CCW |

Spindle rotates in CCW. |

|

H ZUpper |

Z axis would halt at this position which is related to StartZ before and after cutting. |

|

C CutDir |

CW |

Direction of cutting route is CW. |

CCW |

Direction of cutting route is CCW. |

|

K StepWidth |

Width per cut. Must less than the diameter of selected tool. Set in percentage of tool diameter. |

|

Q StepDepth |

Depth per cut. Must less than or equal to Depth of geometry. |

|

W FineWidth |

Width of fine cut. Set to 0 if none. Must less than or equal to StepWidth and tool radius. |

|

D FineDepth |

Depth of fine cut. Set to 0 if none. Must less than or equal to StepDepth. |

|

F Feedrate |

Feedrate of XY moving. (mm/min) |

|

S ZDirFeed |

Feedrate of Z moving. (mm/min) |

|

E FineFeed |

Feedrate of fine cut. (mm/min) |

|